ADD TIME: 2021-11-19

CLICK COUNT: 530

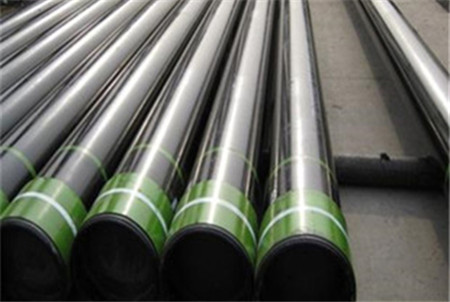

Casing pipe are used to support the well wall during drilling and after completion to ensure the drilling process and the operation of the well after completion. Several layers of casing are used in each well, depending on the drilling geology. Cement cementing should be used after oil casing well, which is different from tubing and drill pipe and can not be used repeatedly, due to one-time consumption data. Therefore, the consumption of oil casing accounts for more than 70 percent of the total oil well pipe. Here is a brief introduction to the functional features of the use of oil casing.

The casing pipe is the lifeline to keep the well running. Because of the different geological conditions, the underground stress state is complex, the comprehensive effect of tension, pressure, bending and torsion stress on the pipe body, which puts forward a higher demand on the quality of the casing itself. Therefore, the functional requirements of oil casing are different in different application scenarios. Petroleum casing can be divided into: conduit, surface casing, technical casing and oil layer casing. According to the rule of wall thickness of welded pipe, there are two kinds of general petroleum casing and thickened petroleum casing.

Different types of oil casing are used in the process of oil mining: surface oil casing maintenance drilling, to avoid shallow water and shallow gas pollution, support the wellhead equipment and adhere to the casing of other layers; The technical casing separates the pressures at different levels to allow fluid flow and maintain the production casing.In order to install crack prevention equipment, leak prevention equipment and liner in the well, for the maintenance of the well, the drilling mud stratification. In corrosive environment, the oil casing itself is required to have anti-corrosion function.In the local area with complex geological conditions, the oil casing is also required to have the function of anti-bursting and anti-microbial erosion.

How to carry out hydrostatic test for oil casing?